Advanced Technology and Processes Solve an Industry-Wide Problem and Promote Sustainability

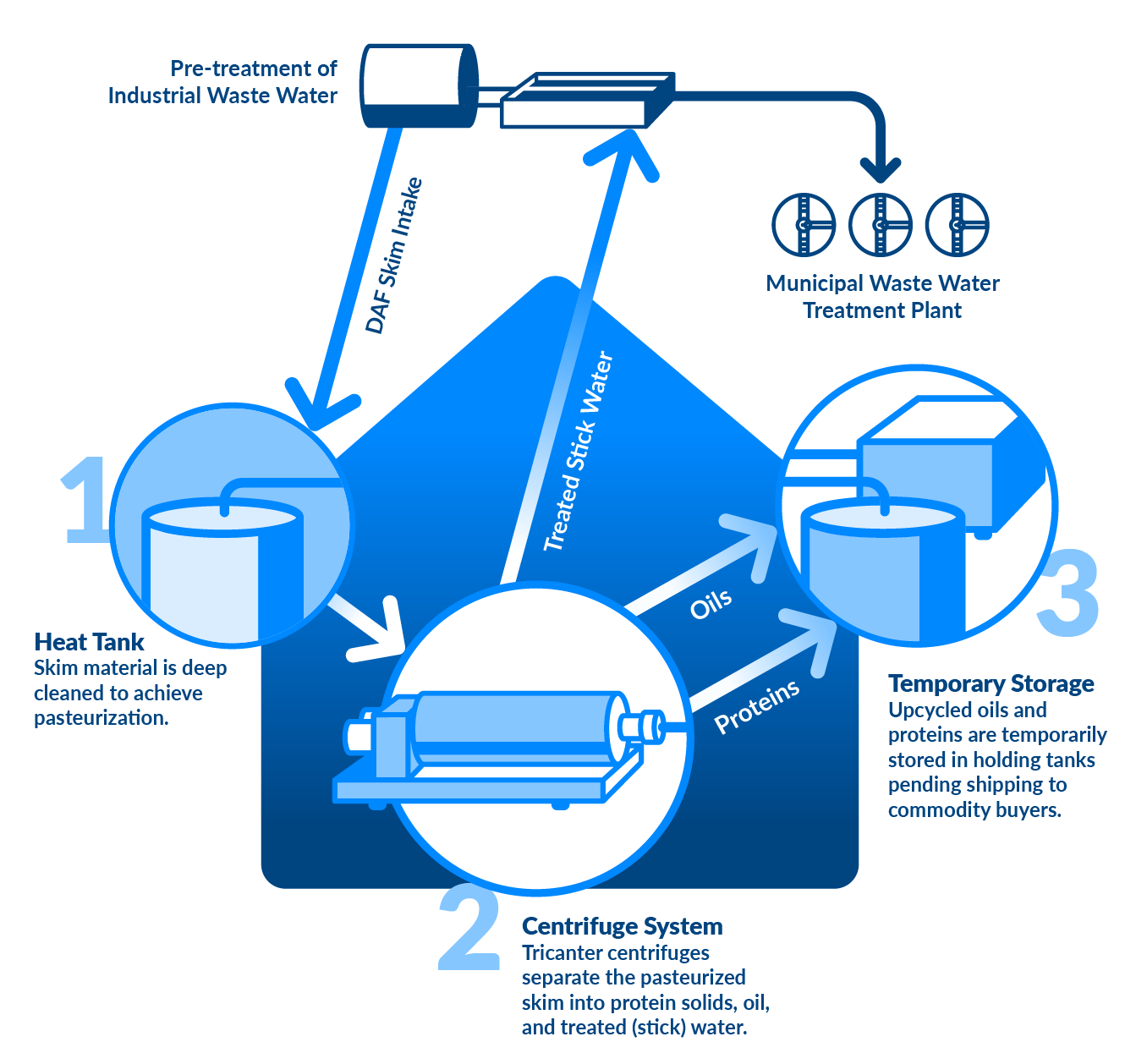

Our advanced FOX (Fat and Oil eXtraction) Technology includes specialized heat tanks and tricanter centrifuges to clean and then separate DAF skim into three distinct components: protein solids, oil, and stick water. The system is built, operated, and maintained by The Upcycle Company technicians who work on-site at each location.

Our Technology

Main components

- Our proprietary patent-pending FOX (Fat and Oil eXtraction) Technology includes specialized heat tanks to deep clean DAF skim to achieve Pasteurization

- Tricanter centrifuges separate the Pasteurized skim into protein solids,oils, and stick water

- Storage tanks temporarily store protein solids and oils for shipment

Benefits

- Reliable – suitable for 24/7 operations

- High capacity – capable of processing more than 5,000,000 gallons of wastewater per day

- Effective – ~high FOG and TSS capture rates enhance the efficiency of wastewater treatment plants

- Immediate upcycling of DAF skim enables the creation of high-quality co-products

FOX Technology On-Site Facility Components